Environmental Protection

Air Pollution Control

Optimize Air Pollution Prevention Equipment

FPG has been actively improving our control of air pollution and accumulated considerable experience. To duly perform our environmental protection work, we continued to adopt the optimized process technologies and comprehensive air pollution prevention systems, including advanced air pollution prevention equipment such as the selective catalytic reduction (SCR) equipment, flue gas desulfurization (FGD) equipment, low NOx burner, high-temperature oxidizer, activated carbon adsorption system, close coal storage and transmission systems. Together with appropriate preventive maintenance, training, and operations, we allow all equipment to exert their optimized processing effects to duly perform our pollution prevention work. At present, FPC's pollution control results have surpassed national standards and are on a par with the performance of global optimization standards. In 2021 the SOx and NOx for our unit products had decreased by 0.100 Kg/Tons and 0.280 Kg/Tons, respectively.

To better meet international standards and comply with government policies implemented in line with the Montreal Protocol, FPC has stopped the use of Halons, CFC-11, CFC-12, and other substances that cause destruction of the ozone layer. R-134A and R-140A are currently used as the main cooling agents.

Stringent VOC Reduction and Odor Control

Mailiao Industrial Complex is the first industrial park in Taiwan to implement the control of the total quantity. In addition to the various pollutants that have met the requirements of EIA, it continues to actively promote reduction and improvement of VOC reduction. FPG has made improvements of a total of 689 cases in accumulation by 2021 with an investment of NT$4.322 billion.

To prevent the further effusion of VOC, reduce the use of raw materials, and minimize the occurrence of product leakage and complaints on odors from citizens, FPG invested in the purchase of 39 GasFindIR for military use in the USA, which could rapidly find the source of leakage via infrared to allow immediate improvement. According to the statistics, the abnormal rate of VOC emission concentration of equipment and elements at Mailiao Industrial Complex from the audits conducted by the environmental protection authority has been reduced year by year, reaching 0.024% in 2021.

Water Pollution Control

For sewage incurred at different industrial complexes, FPG properly organizes the sewage processing facilities based on the source of occurrence and characteristics of sewage, including physical chemistry processing of neutralization, precipitation, and flotation and methods of biological treatment and membrane treatment. We established the dedicated sewage processing department and personnel according to the responsibilities and regularly organize educational training to effectively manage sewage processing, allowing the quality of water emission to comply with the national effluent standards. Furthermore, we adopt the ocean outfall (emission of Mailiao Industrial Complex into the Taiwan Strait), stream outfall (emission of Jinxin Industrial Complex into Nankan River in Taoyuan, Xingang Industrial Complex into Niu-Ch'ou River Chiayi, and emission of Renqu Industrial Complex into Houjin River in Kaohsiung), or emission to nearby receiving water body after being processed by the sewage treating plant of the industrial park.

.png)

Waste Management

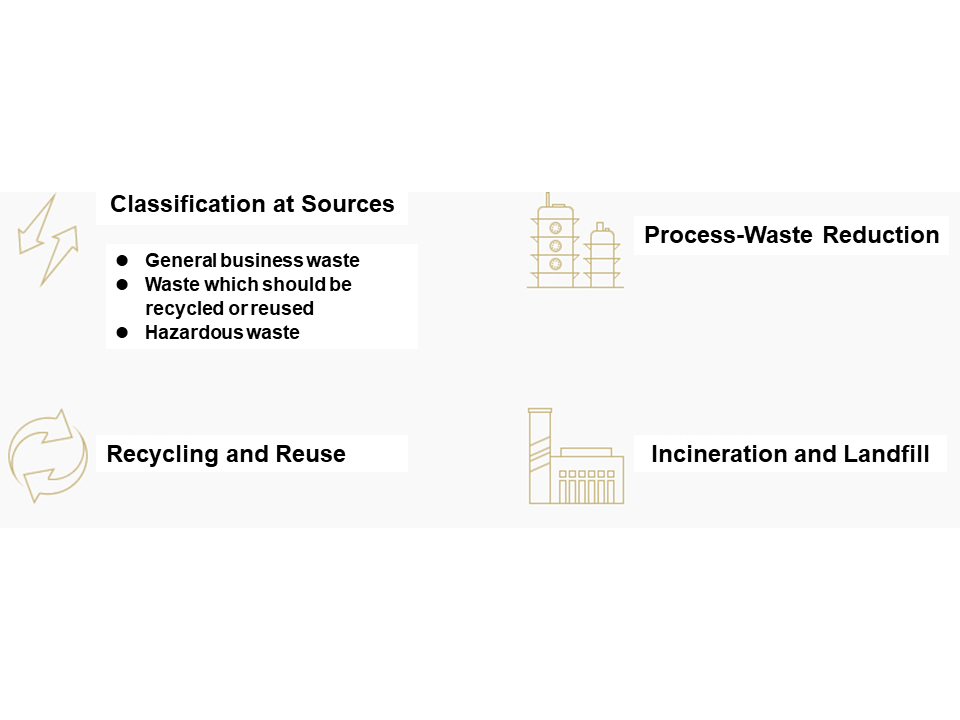

Waste management is divided into four stages: operations such as classification at sources, process-waste reduction and recycling and reusing to reduce the waste amount for incineration and landfill, and to achieve zero waste and zero landfills as positive goals.

Reuse is a priority in waste outsourcing disposal, followed by incineration and landfill. In 2021, the waste generated by FPG was 2,731,762 tons in total; by adopting measures of classification, recycling, reuse, and reusing, we recycled and reused a total of 2,592,220 tons of waste, accounting for 94.89%.