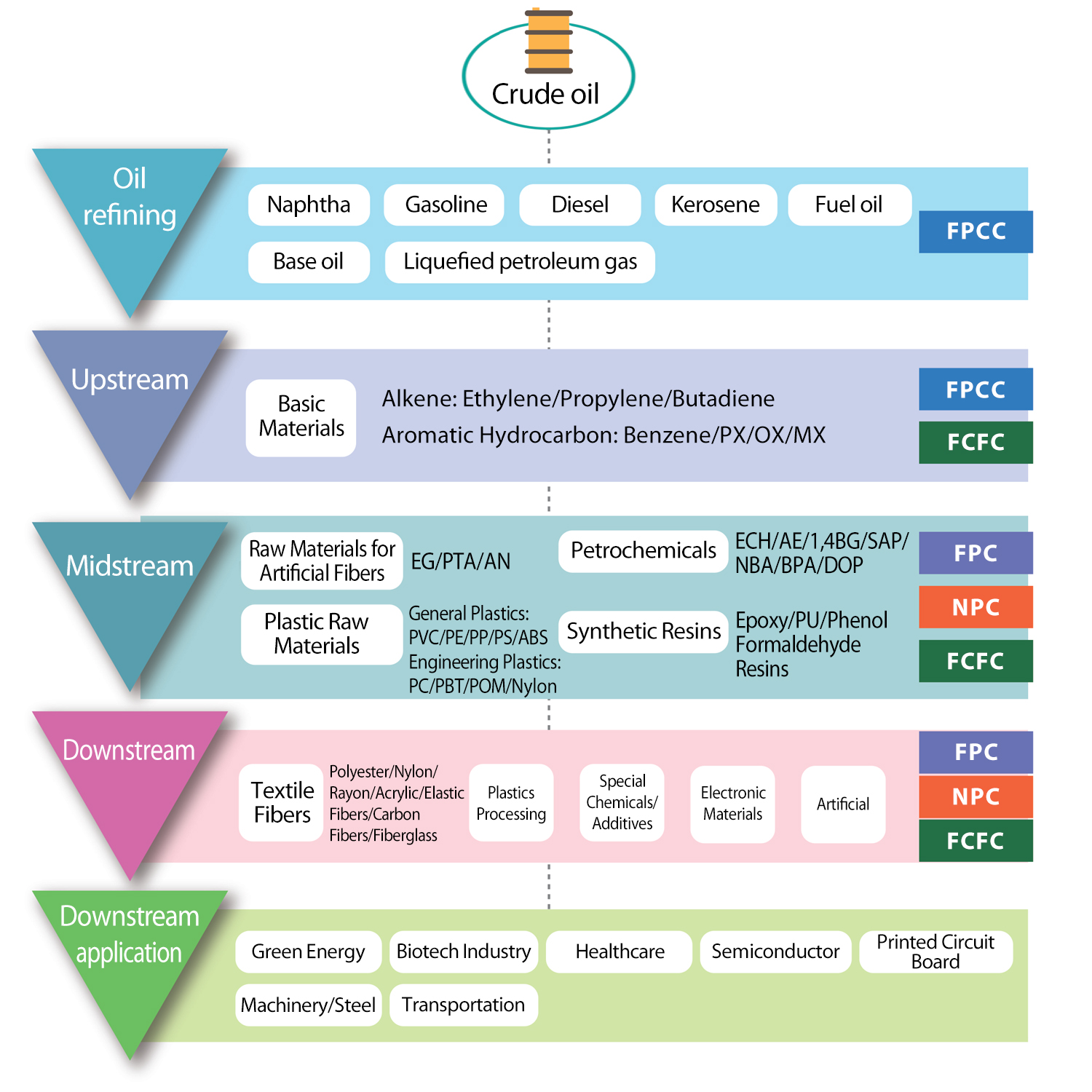

Expand upstream petrochemical industry and increase raw material self-sufficiency rate

Before the 1980s, Taiwan's petrochemical basic raw materials were only produced by CPC Corporation. Due to the long-term shortage of raw materials, the domestic ethylene self-sufficiency rate was only 38% at that time, and the remaining 60% had to be imported from overseas at higher prices, resulting in the development of the middle and downstream petrochemical industries being limited. In order to alleviate the shortage of raw materials, FPG put forward a plan to build a naphtha cracking plant. In 1986, the plan was approved by the government and the construction was started in Mailiao, Yunlin. The construction adopted a more complete and innovative design for equipment and pipeline transportation than that of CPC Corporation. In 1998, the oil refinery and naphtha cracker were completed successively. After the complex was put into operation, the domestic ethylene self-sufficiency rate increased from 38% to 92%, which not only reduced dependence on imports, but also saved transportation costs, ensured stable material supply, and strengthened Taiwan's competitiveness in the global market.

At present, FPG's oil refinery has a daily capacity of 540,000 barrels, which is equivalent to refining 25 million tons of crude oil per year. The refinery is one of the world's top ten refineries and can supply naphtha, gasoline, diesel, jet fuel, and liquefied petroleum gas. Naphtha is then used by related factories of the conglomerate. Currently, the company has three naphtha plants, which respectively produce basic petrochemical raw materials such as ethylene, propylene, and butadiene for the downstream production of chemicals and plastic products.

FPG Production Capacity of Petrochemical Products (gathered from annual report 2021)

- Petrochemical Products

- Product

Category - Main Purposes of Each Product

- Annual

Production Capacity

- Crude Oil Refining

- -

- Production of Naphtha and Other Oil Products

- 54,000 barrels/per day

- Oil Products

- Gasoline

- Fuel for Vehicles and Machinery

- 6,000,000 KL

- Oil Products

- Jet Fuel/Kerosene

- Jet Fuel, Heating Oil, Industrial Oil, Fossil Fuel

- 2,500,000 KL

- Oil Products

- Diesel

- Fuel for Vehicles and Machinery, Fuel for Power Generators

- 10,000,000 KL

- Oil Products

- Fuel Oil

- Fuel for Ship Boilers, Heating Furnaces, Metallurgical Furnaces, and Other Industrial Furnaces

- 1,000,000 KL

- Oil Products

- Liquefied Petroleum Gas (LPG)

- Household and Industrial Fuel

- 730,000 MT

- Petrochemical Raw Materials

- Ethylene

- Production of Plastic Raw Materials (Polyethylene, Polyvinyl Chloride, etc.)

- 2,935,000 MT

- Petrochemical Raw Materials

- Propylene

- Production of Plastic Raw Materials (Polypropylene, Acrylonitrile, n-Butanol)

- 2,368,000 MT

- Petrochemical Raw Materials

- Butadiene

- Production of Plastic materials (ABS Resin), etc.

- 447,000 MT

- Petrochemical Raw Materials

- Aromatic Hydrocarbons

- Production of Chemical Raw Materials

- 3,880,000 MT

The other kind is produced from naphtha and aromatic hydrocarbon mixtures as raw materials, namely, the aromatic hydrocarbon products, including benzene, o-xylene (OX), and p-xylene (PX). FPG's benzene is all used to produce styrene (SM) and phenol (Phenol). Styrene (SM) is then used as a raw material for downstream production of polystyrene (PS) and acrylonitrile-butadiene-styrene (ABS); phenol (Phenol) can be used to produce Bisphenol A (BPA), and Bisphenol A (BPA) can be used to produce polycarbonate (PC); p-xylene (PX) can be used to produce terephthalic acid (PTA) as the main raw material for synthetic fibers.

In order to exploit oil overseas, FPG established a subsidiary in the United States in 2006. Considering that the United States is rich in oil and natural gas reserves, well-known for its friendly investment environment, and has mature shale gas extraction technology, FPG has in recent years successively launched investment projects in ethylene products in Texas and Louisiana to improve the competitiveness of ethylene-related derivatives.

From traditional to modern, FPG continues to strive towards safety, eco-friendly operations and high value.

FPG has continued to invest in the upstream petrochemical industry over the years to propel the development of related mid-and downstream industries. In addition to the pursuit of quality, FPG has comprehensively promoted process safety management in recent years, and is committed to process safety assessment, safety inspections before start-up, equipment reliability testing and updates. The most advanced ultrasonic detectors are used to regularly monitor pipelines. FPG also has a fire rescue team to maintain safety at any time. Since 2011, FPG has spent about 14 billion dollars and 2 years to gradually replace the old pipelines. There are more than 1,000 pipelines with a total length of more than 1,200 kilometers. All pipelines are painted with 3 coatings, and the durability has been increased to more than 30 years to resist the harsh weather conditions in the coastal area of Mailiao.

With respect to climate change, FPG continues to invest in energy conservation, carbon reduction and greening. Also, in line with the government's circular economy policy, FPG actively invests in technology research and development, and cooperates with large domestic and foreign manufacturers to establish high-value production bases. FPG aims to play a leading role in upgrading the petrochemical industry to create a green economy.

Key Projects

.Continue to develop environmentally friendly products to reduce the sulfur content of jet fuel, diesel, marine fuel, and others.

.Build an ethane cracking plant with an annual production capacity of 1.2 million tons and 600,000 tons of propane dehydrogenation (PDH), which is expected to be put into operation in 2025 (Louisiana, USA).

(FPG, Dec. 31, 2022)

Oil Products

The substances produced by the fractional distillation and chemical reactions of crude oil, e.g., gasoline, diesel, liquefied petroleum gas (LPG), jet fuel, kerosene, and asphalt, are mainly used as power source for vehicles and machinery.

Petrochemical Raw Materials

The petrochemical raw materials produced by the cracking of naphtha, including ethylene, propylene, butadiene, aromatic hydrocarbons and other raw materials, are used for the middle and downstream production of chemicals and plastic products.