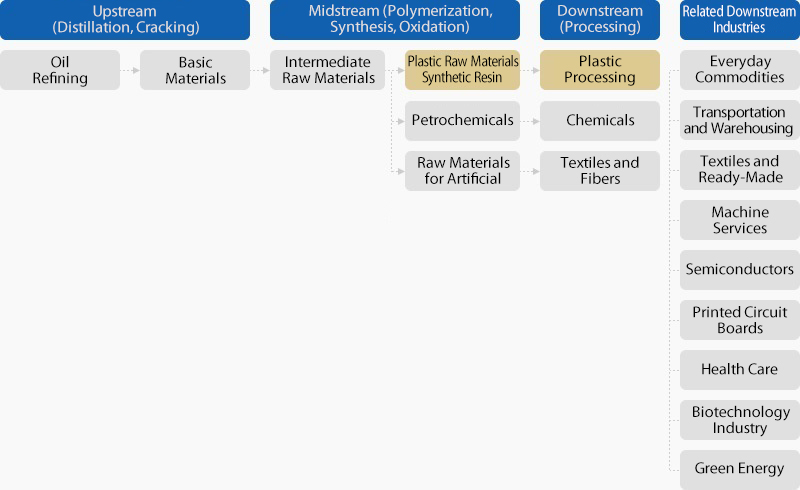

Sustaining Petrochemical Industry by Building Comprehensive Plastic Industry Value Chain

The plastics industry was the first industry Formosa Plastics Group invested in. In the 1950s, FPG's founder, whose mainly ran business involving rice and wood, accepted the investment advice made by the then Economic and Security Committee in response to the government's economic development plans, and started the production of plastic raw material—polyvinyl chloride (PVC powder). Following the large scale production of PVC powder, FPG established plastic processing plants successively to make PVC powder into PVC sheets and Synthetic Leather.

Show more

Due to the domestic market demand at home and abroad and FPG's diversification strategy, FPG continued to expand its production capacity, and began manufacturing plastic additives and non-PVC plastic raw materials, such as polyethylene (PE powder), polypropylene (PP powder), etc., providing more diverse options for the plastics industry supply chain. FPG's venture into oil refining in the 1990s also added momentum to its plastics business. In addition to the production of raw materials, FPG also has years of manufacturing experience in plastic processing. With upstream and midstream vertical integration, FPG strives to provide products that are competitive in price and quality.

With Taiwan as the coordinating center, FPG makes good use of its production and sales networks in East Asia, Southeast Asia and North America. In a rapidly changing market, FPG responds to customer needs in a timely manner, effectively collects market information, and utilizes the product development strengths and technical services of the R&D departments to provide new products in line with industry trends.

Key Projects

. Manufacturing and marketing of plastic processing by Formosa Industries Corporation (Vietnam).

. Global integrated marketing operations (Europe and America) with FPG companies in America.

(FPG, Dec. 31, 2022)

Plastics

Plastic raw materials are basic raw materials produced by cracking naphtha, such as ethylene, propylene, styrene, and p-xylene. Through chemical reactions, these basic raw materials go through polymerization and become polymers. We call this type of polymers "plastic raw material." These plastic raw materials can be provided for downstream secondary processing factories, electronic parts manufacturers and other manufacturers for processing and production.

- General Plastics (Polyvinyl Chloride, PVC)

- General Plastics (High-density Polyethylene, HDPE)

- General Plastics (Low-density Polyethylene, LDPE)

- General Plastics (Linear Low-density Polyethylene, LLDPE)

- General Plastics (Polypropylene, PP)-Formosa Plastics Corporation

- General Plastics (Polypropylene, PP)-Formosa Chemicals & Fibre Corporation

- General Plastics (Polystyrene, PS)

- General Plastics (ABS)

- Engineering Plastics (Polyoxymethylene, POM )

- Engineering Plastics (Polycarbonate, PC)

- Engineering Plastics (Other)

- Thermo seting plastics (PU)

- Thermo seting plastics (UP Resin)

Processed Plastic Products

Intermediate goods of different shapes, sizes, colors, and functions, processed according to the material type and characteristics.

- Flexible PVC Sheets

- Rigid PVC Sheets

- PET Metallized Sheets

- A-PET Film and Sheet

- PP Synthetic Paper

- Liso Films

- Window Films

- PU Synthetic Leather

- TPU Synthetic Leather

- Plastic Pipe & Fitting

- Plastic Injection Molding Products

- Plastic Pallet

- PVC Rigid Plate

- BOPP Films

- CPP Films

- Interior Building Materials

- Eco Plastic Panel & Decking

- PVC Vinyl Windows and Doors

- Fiberglass SMC Doors and Composite Door Frames

- Fiberglass SMC Fire Rated Doors

Other Additives

Plastic products may deteriorate due to heat and force during processing or degrade and become discolored over time. Therefore, additives are used to improve processing. In order to enhance the performance of plastic products, additives are also used to make the product features meet customer requirements. There are also masterbatches and adhesives used in processing.