FSET Announces Completion of Battery Cell Factory in Changhua Coastal Industrial Park

2024 / 10 / 04

Formosa Smart Energy Tech Corp. (FSET) has completed the first phase of its battery cell and module factory in Changhua Coastal Industrial Park. In November, FSET will officially start its mass production. This year, at ENERGY TAIWAN 2024, FSET will specially integrate digital media to create a "battery cell corridor," showcasing the process technology of battery cells for the first time. Additionally, significant progress has been made in solid-state battery research and development, with the pilot production line set to be completed in two phases starting in October 2024. The exhibition will feature an interactive laboratory concept to demonstrate the high safety and application scope of solid-state batteries. FSET showcases a diverse and forward-looking layout through its existing mature product lines and next-generation technologies, fully addressing current demand in the renewable energy market and future trends.

FSET’s Chairperson, Sandy Wang, announces the official completion of its subsidiary Formosa AdvEnergy Technology Corporation's 2.1GWh lithium iron phosphate (LFP) cell and module factory located in Changhua Coastal Industrial Park. Since breaking ground in 2023, the project has involved over 500 days and nearly 170,000 workers in construction. The construction team has worked tirelessly, investing countless resources while adhering to the highest quality standards and strict safety regulations. This facility is now the largest and most automated LFP cell production base in Taiwan, encompassing eight major processes: Slurry Preparation, Coating, Calendering & Slitting, Winding, Assembling, Cell Baking, Infusing, and Formation. All processes are locally produced and managed, completing a crucial piece of the domestic battery industry chain. This milestone will significantly enhance Taiwan's competitiveness in the global renewable energy market.

Sandy Wang points out that the world is accelerating toward a low-carbon transition, with remarkable advancements in energy storage, electric transportation, and emerging energy technologies. The market shows significant potential demand for innovative solutions. In response to this continually changing industry landscape, FSET is deeply investing in key technologies and actively planning ahead. FSET has acquired 24.83 hectares of land to initiate the preparatory work for the second phase of the battery cell and module factory. The total production capacity for both phases is expected to expand to over 5 GWh. Additionally, FSET is constructing a battery recycling facility to complete the circular economy system, laying a solid foundation for the long-term development of renewable energy and leading the transformation of the industry and society.

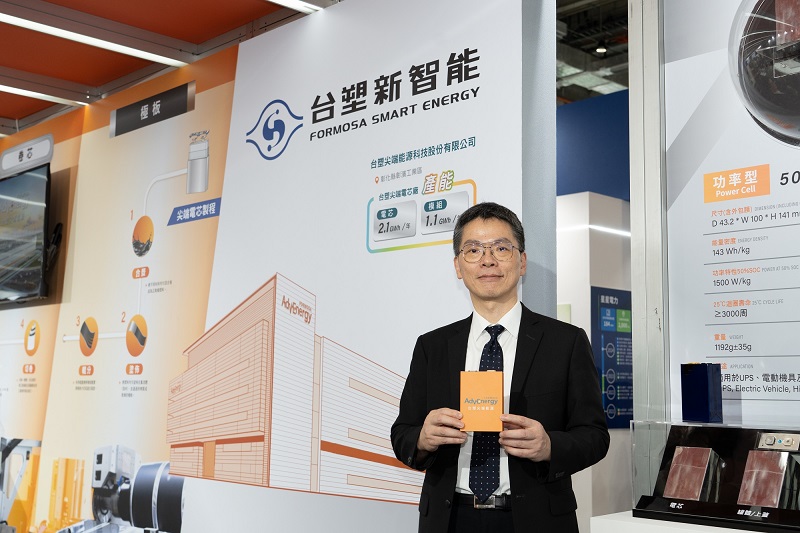

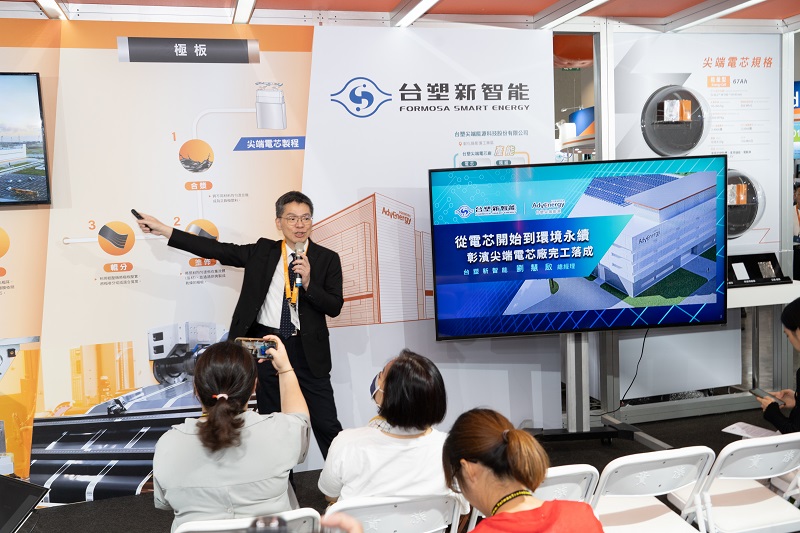

FSET General Manager, Stephen Liu, states that under the current international political and trade fluctuations, Taiwanese battery cells are demonstrating significant competitive advantages. As a result, even before the completion of the battery cell factory, FSET has received numerous inquiries for orders from domestic and international companies, including those for energy storage systems (ESS), uninterruptible power supplies (UPS), and electric vehicles (EV). This year, FSET showcases battery modules for electric buses for the first time. In the future, FSET will continue to collaborate with automotive manufacturers to develop power battery packs using domestically produced cells with high energy density and long cycle life, suitable for various electric commercial and passenger vehicles.

Stephen Liu states that in order to develop next-generation battery technology, and unlike the majority of the industry that still relies on half-solid or quasi-solid batteries containing electrolyte, FSET has partnered with Ming Chi University of Technology (MCUT) to invest in solid-state battery technology that contains no electrolyte. Currently, it is in the laboratory research and validation stage, with ongoing tests and optimizations. In addition, 19 patents have been granted in Taiwan, the United States, China, Japan, and other countries, with an additional 10 patent applications in process. The first section of the pilot production line is expected to be completed in October, focusing on the manufacturing processes of three key components: the positive electrode, the negative electrode, and the solid-state electrolyte membrane. The second section is expected to be completed next year, involving the stacking and assembly of soft pouch batteries, which will first be tested in consumer electronics.

ENERGY TAIWAN takes place from October 4th to 6th, 2024. FSET will showcase a battery cell corridor, the latest residential, commercial, and industrial energy storage systems (ESS), as well as diverse applications of microalgae technology. FSET will also offer interactive experiences regarding solid-state batteries and battery recycling technology, showcasing its comprehensive layout in the renewable energy sector and contributions to a sustainable environment.