With the implementations of the domestic health risk assessment and the epidemiological survey , there isn’t a consensus on whether it is necessary to pass strict review before publishing results or not. This caused a lot of unauthorized publications of information that is not supported by scientific evidence. Some news media have opportunistically written misinformed headlines such as "National Taiwan University Research: High cancer risk in Taixi Village, Changhua, is related to No.6 Naphtha Cracker" and "Scholars worry about fatal pollution after Guoguang Petrochemical Project". Such headlines caused most people to have doubts about the health of employees in the petrochemical industry and the health of nearby residents. All the production processes in the Mailiao Industrial Park of Formosa Plastics group (FPG) adopt the BACT (Best Available Control Technology) for pollution prevention to ensure a good living environment for local residents. In addition, to protect the health of front-line employees, FPG entrusted a third-party agency to measure the employees' exposure to VOCs (volatile organic compounds) in the Mailiao Industrial Park. The measured values of the monitored substances are far below the national regulatory values. In fact, the monitoring methods and results by the third-party agency have been published in international journals and academic conferences.

The implementation of employees' exposure to VOCs in Mailiao industrial park

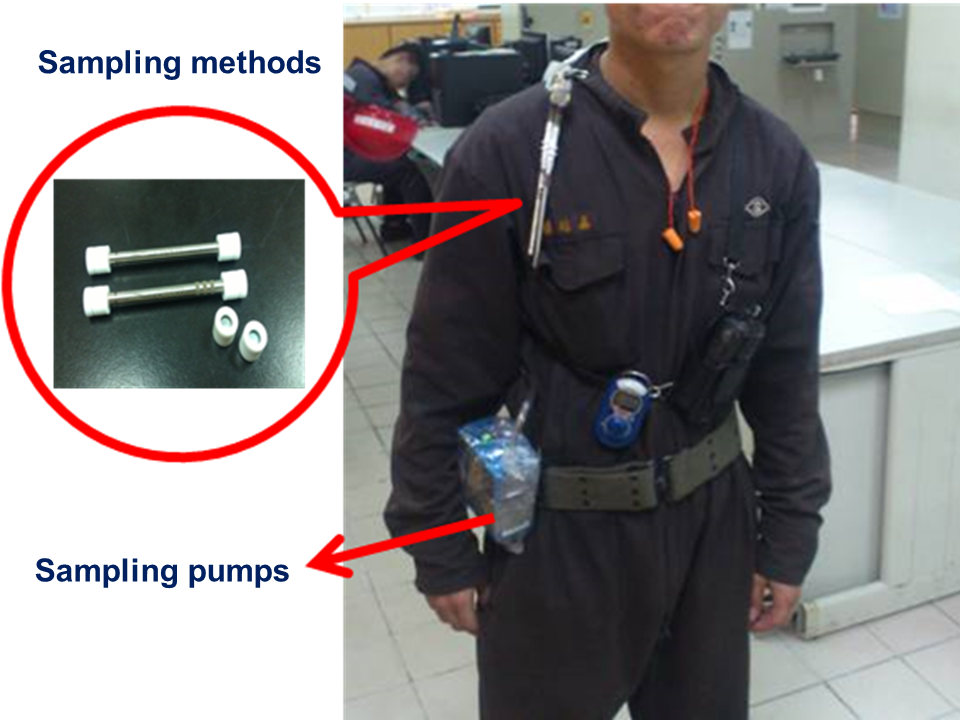

Since 2012, other than monitoring the work environment every six months in accordance with the laws and regulations, FPG has also commissioned the Taiwan Occupational Hygiene Association to conduct a project to monitor the employees' exposure to VOCs in the Mailiao plant. Operators should carry personal sampling kits to measure employees' exposure to VOCs eight hours a day during work. The values of 3,688 employees' exposure to VOCs during work in Mailiao Industrial park, measured by the Taiwan Occupational Hygiene Association, were far below the national regulatory values. In addition, the values of 234 employee’s short-term exposure to VOCs working in equipment maintenance and pipeline repair were also far below the national regulatory values.

Developing monitoring methods to accurately measure the exposure in a work environment

In order to better understand employees' exposure to VOCs and to simplify the process of sampling analysis, Mailiao Industrial Park uses the standardized analysis methods of the NIOSH (National Institute of Occupational Safety and Health) in the United States and the British HSE (Health and Safety Executive) as a reference. Thermal desorption units have been developed for air sampling along with Gas Chromatography - FID - Flame Ionization Detector (GC-FID) that are used to measure VOCs values.

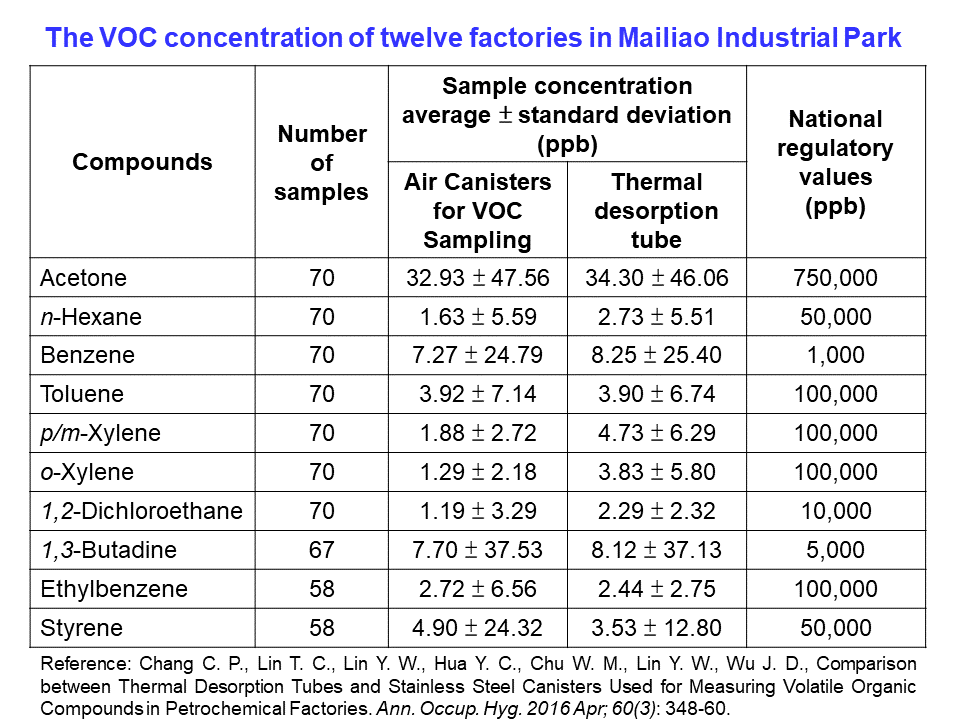

The best way to monitor VOCs is by using gas sample cylinders (together with a gas chromatography mass spectrometer). However, sample cylinders are unhandy to use because they are large and heavy, so they are not suitable for employees to carry. Instead ,during on-site inspection, sample cylinders are used together with a gas chromatography mass spectrometer to verify the suitability of the thermal desorption units in monitoring the employees' exposure to VOCs . In addition, while the sample cylinders sample VOCs, they also verify the accuracy of the thermal desorption units. In 2012, twelve factories in Mailiao Industrial Park went through such verification process (including Formosa Plastics Corporation Acrylonitrile Factory, Acrylate Factory, Plastic Factory, Nan Ya Plastics Plasticizer Factory, Haifeng Bisphenol A Factory, Haifeng 1,2-Butanediol Factory, Formosa Chemicals & Fibre Corporation PABS Factory, Formosa Petrochemical Corp. terminal area, oil refinery plant No.3, Alkene plant 1, Alkene plant 2, Alkene plant 3, etc.). The results showed that there was no significant difference between the measured values of the two sampling methods. This indicates that the thermal desorption units, together with the GC-FID, can be used to accurately measure employee's exposure to VOCs. This method can not only shorten the flow of sample processing, but also reduce the detection limit of VOCs to the ppb level. Therefore, this method has been subsequently used to sample and analyze VOC values. In 2016, the above-mentioned results were published in the Annals of Occupational Hygiene.

The Annals of Occupational Hygiene is a journal published by Oxford University and the British Occupational Hygiene Society (BOHS). They commit to advocate for healthy work environments. The journal mainly publishes papers that discuss (1) various hazards (such as chemical hazards, physical hazards, and biological hazards) and other human-induced hazards (such as formation mechanism, employee exposure, hazard distribution, etc.); (2)factors that control workplace exposure (such as monitoring the work environment and controlling measures, etc.); and (3) occupational safety and health related issues (e.g. epidemiological data, risk management, employee education and training, etc.). Although this journal invites scholars from all over the world to submit papers, it has a strict review process to ensure the quality of each paper. The journal will not publish a paper if it does not meet the following conditions: (1) the findings are of regional characteristics and cannot be used universally; (2) the paper provides insufficient information on the health hazards of pathogenic factors; and (3) the paper includes non-occupational exposure controls. The papers published in this journal provide the latest research results on the assessment and control of work-related health hazards and risks, which can be used as references for improving work environments and promoting the health of employees. It is a leading research journal in the field of international occupational health.

Results in the monitoring of employee exposure show that the workplace is saf

1. FPG explains the results in the monitoring of VOCs to its employees:

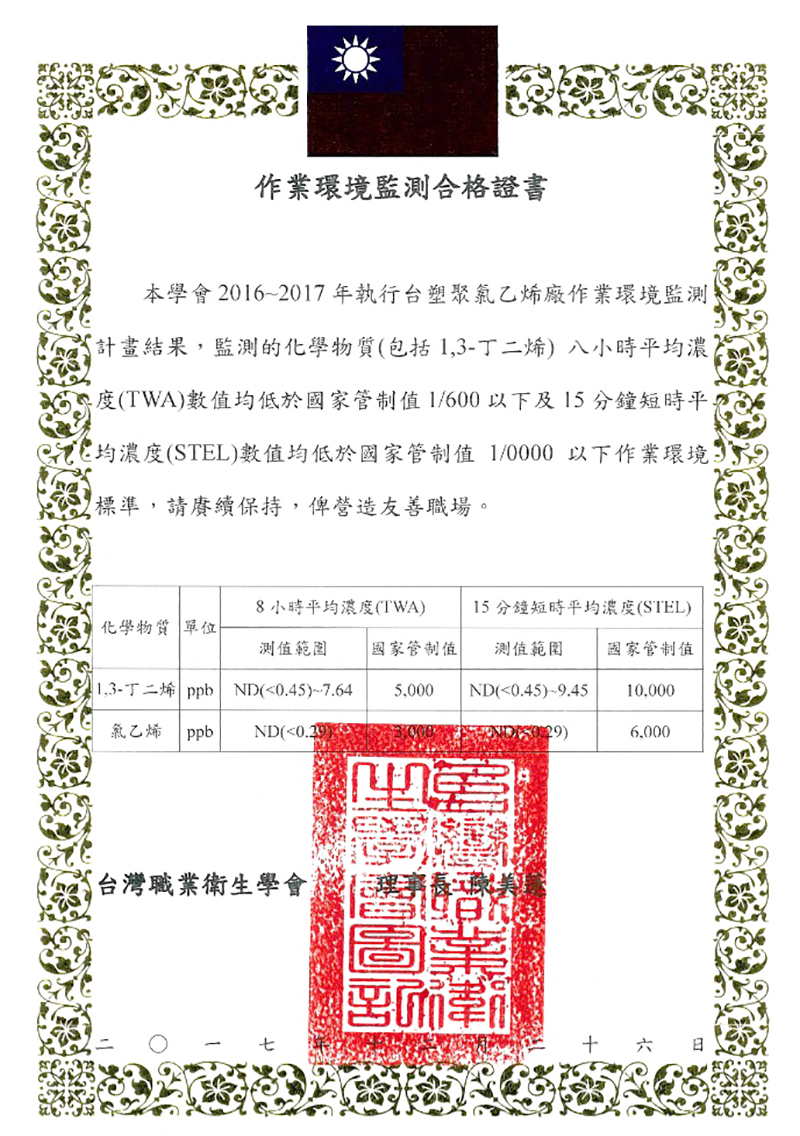

The Taiwan Occupational Hygiene Association has analyzed the results on employee exposure based on national regulatory values and concluded that the levels of exposure will not cause health hazards. To help employees understand the exposure of VOCs in the workplace, Taiwan Occupational Hygiene Association has issued a certificate for factories that are in compliance with the statutory requirements. The results have also been posted on the billboards in factories in hopes of encouraging the employees to work together in creating a friendly workplace and a safe production environment.

2. An explanation is given to external parties to confirm that the work environment for employees is safe.

The Safety, Health and Environment Center and the Taiwan Occupational Hygiene Association compiled and analyzed data regarding the monitoring of VOC and VCM exposure (including short-term exposures). They used these data to assure external parties that the work environment is safe for employees. They also informed them on the status of the current workplace safety and its implementations. Also, a paper was published in the "Taiwan Occupational Hygiene Symposium". It is an important symposium held every year for the industry, government, and academia.

FPG Safety, Health and Environment Center, and the Taiwan Occupational Hygiene Association worked together to publish two papers in the Taiwan Occupational Hygiene Symposium in 2017. They were titled "Monitoring VOC Exposure on Workers in a Petrochemical Plant", and “An assessment of exposure to vinyl chloride among workers in petrochemical plants". The results showed that the values of VOC exposure, e.g. benzene, 1,3-butadiene, and vinyl chloride, in Mailiao Industrial Park , were far lower than the national regulatory value. FPG also explained to the industry, government, and academia that the design of Mailiao Industrial Park and its operations are safe enough to ensure the health of the employees and the health of nearby residents.

In 2018, FPG further published three more papers in the Taiwan Occupational Hygiene Symposium., They were titled "A description of exposure to multiple VOCs among petrochemical plant workers" ,"Monitoring short-term exposure to multiple VOCs in a petrochemical plant", and "An assessment of exposure to vinyl chloride among petrochemical plant workers". In respective order, the summaries of the papers are as follows :

(1) A description of exposure to multiple VOCs among petrochemical plant workers

The study monitored the exposure of fourteen different VOCs on 3,688 employees. The monitoring period of VOC exposure took place from 2012 to 2017 in twenty-one factories in Mailiao Industrial Park. The values of acetone, p-xylene, o-xylene, and toluene were higher during the five year period, with average values of each VOC falling between 6.9~14.8 ppb. However, the highest values of the four VOCs were lower than one-fifth of the statutory values. The values of other VOCs, including benzene and 1,3-butadiene, had not changed much during the five year period, with average values of each VOC falling between 2~4.6 ppb. These values represented the effectiveness of Mailiao Industrial Park's effort in controlling and managing VOC emissions from the manufacturing pipeline and equipment. FPG had to continue to explain to the industry, government, and academia that its employee exposure to VOCs is way lower than national regulatory requirements.

(2) Monitoring short-term exposure to multiple VOCs in a petrochemical plant

The study monitored the short-term exposure of fourteen different VOCs on 234 people who engaged in sampling, feeding, tanker preparation, equipment maintenance, pipeline overhaul, and other operations. The monitoring period took place from 2014 to 2017 in twenty-one factories in Mailiao Industrial Park. The average values of each VOC were between 2.6 and 414.7 ppb. The maximum value of each VOC was less than a ninth of the national regulatory value. The results on monitoring the short-term exposure of VOCs on employees and the results in the above-mentioned paper mutually confirm that the workplace for employees is safe.

(3) An assessment of exposure to vinyl chloride among workers in petrochemical plants

The study monitored the exposure of vinyl chloride on 359 employees during work in Mailiao's plastics and vinyl chloride factories. The monitoring period took place from 2013 to 2017. The maximum value of vinyl chloride was 57.9 ppb, which is less than a fifth of the regulatory value and far below the strictest international standard (1,000 ppb). The value was also below Western European and North American standards (400 ppb) that the European Environment Agency requires. Even though the data on the short-term exposure of vinyl chloride on twenty-two employees had a maximum value of 234.5 ppb during annual maintenance, , which was lower than the national regulatory value. This indicated employees were more likely to be exposed to vinyl chloride at higher levels during annual maintenance. Therefore, providing personal protective equipment for employees is crucial when engaging in on-site inspections, on-site product sampling, and pipeline maintenance.

(FPG, Aug 29, 2018)